Many thanks for choosing HOWO trucks ! This manual is about maintenance of HOWO series heavy duty trucks.

To ensure the normal life of vehicles and obtain the good economic benefit, all the instructions of the operation and maintenance requirements mentioned in this manual need strictly to be followed.

Pure fule in accordance with the quality requirement is required to be used during the vehicle's running. All choosen oil, lubricating oil, hydraulic oil, etc . for vehicles shall be consistent with the provided grades of this manual .

Vehicle Service Conditions

Table 1 Service Conditions of Vehicle

|

WGⅠ |

WGⅡ |

WG Ⅲ |

|

Poor conditions (Severe cold or hot climate, high dust content, used in construction site or bus, municipal engineering vehicle, snow sweeper, fire-fighting engine) or vehicles with annual mileage less than 20,000km or with running hours less than 600h. |

Vehicle with annual mileage less than 60,000km, medium-short distance transportation (For cargo delivery) |

Vehicles with annual mileage over 60,000km, long distance transportation |

Table 2 Cycle of Maintenance

|

Service Conditions Items |

WGⅠ |

WGⅡ |

WGⅢ |

|

First-time Check |

After running 30~50h |

After running 1500~2000km |

After running 1500~2000km |

|

Routine Check (P) |

Every 5000km Every 150h |

Every 1×104km |

Every 1.5×104km |

|

(WD1) |

Every 1×104km Every 300h |

Every 2×104km |

Every 3×104km |

|

(WD2) |

Every 2×104km Every 600h |

Every 4×104km |

Every 6×104km |

|

(WD3) |

Every 4×104km Every 1200h |

Every 8×104km |

Every 12×104km |

|

(WD4) |

Every 8×104km Every 2400h |

Every 16×104km |

Every 24×104km |

Maintenance Items

1. Regular Maintenance Items

1.1Check hand brake and service brake;

1.2Check illuminating lamps, signal lamps and indication lamps (oil pressure, pressure in air reservoir, air filter maintenance indicator and battery charge indicator, etc.);

1.3Check the working mode of starter, alternator and battery;

1.4Check tire pressure and condition;

1.5Check the level of engine oil, coolant and steering hydraulic oil;

1.6Drain water from air reservoir.

2. Graded Maintenance Tasks

Please refer to the second part for the checking and maintenance of the engine, transmission, front and rear axles, steering gear.

Maintenance items include changing oil, checking and adjustment

|

Cab |

First-time Check |

Routine Check |

1st-grade Service |

2nd-grade Service |

3rd-grade Service |

4th-grade Service |

|

Check the wiper |

· |

· |

· |

· |

· |

|

|

Re-tighten locking handle on driver’s cab |

· |

|

|

· |

· |

· |

|

Re-tighten engine radiator’s cover |

· |

|

|

|

|

|

|

Check oil level of cab tipping hand pump |

|

|

|

· |

· |

· |

|

Check lifting cylinder |

· |

|

· |

· |

· |

· |

Maintenance items include changing oil, examing and adjusting.

|

Check fixation and action of towing hook |

· |

|

· |

· |

· |

· |

|

Re-tighten the bolts on cross member of the frame |

· |

|

|

|

|

|

|

Tighten front and rear leaf spring bolts and brackets |

· |

|

|

· |

· |

· |

|

Check spare tire fixing device |

|

|

|

· |

· |

· |

|

Check and adjust slide rail clearance of leaf spring |

|

|

|

· |

· |

· |

|

· |

|

· |

· |

· |

· |

|

|

Check the fixation of battery |

|

|

|

· |

· |

· |

|

Check the fixation of fuel tank |

|

|

|

· |

· |

· |

|

Electrical System |

First-time Check |

Routine Check |

1st-grade Service |

2nd-grade Service |

3rd-grade Service |

4th-grade Service |

|

Check the working condition of electrical system (Instrument, lamps, wiper, and air conditioner). |

· |

· |

· |

· |

· |

· |

|

Check electrolyte level and cell voltage |

· |

|

· |

· |

· |

· |

|

Check the fixation of battery terminal, coat electrode with grease |

· |

|

· |

· |

· |

· |

|

Check electric tachometer and speed accuracy |

· |

· |

· |

· |

· |

· |

Maintenance items include changing oil, examing and adjusting.

|

First-time Check |

Routine Check |

1st-grade Service |

2nd-grade Service |

3rd-grade Service |

4th-grade Service |

|

|

Drain water from air reservoir |

· |

· |

· |

· |

· |

· |

|

Check leakproofness of air pressure system (With barometer) |

· |

|

· |

· |

· |

· |

|

Check brake lining thickness and adjust brake clearance |

|

|

|

· |

· |

· |

|

Clean wheel brake |

|

|

|

|

· |

· |

|

Check vulnerability of brake pipeline and hoses |

· |

|

|

· |

· |

· |

|

Check brake chamber |

|

|

· |

· |

· |

· |

|

Check footbrake, handbrake and exhaust brake action (When do the trial running) |

· |

|

· |

· |

· |

· |

|

Check ABS |

· |

|

· |

· |

· |

· |

|

Vehicle |

First-time Check |

Routine Check |

1st-grade Service |

2nd-grade Service |

3rd-grade Service |

4th-grade Service |

|

Short distance trial running (Including braking test) |

· |

|

· |

· |

· |

· |

|

Visual check for leakage |

· |

· |

· |

· |

· |

· |

|

Check and tighten cargo body |

· |

· |

· |

· |

· |

· |

Maintenance items include changing oil, examing and adjusting.

|

Lubrication |

First-time Check |

Routine Check |

1st-grade Service |

2nd-grade Service |

3rd-grade Service |

4th-grade Service |

|

|

Water pump |

· |

· |

· |

· |

· |

· |

|

|

Clutch release shaft |

· |

· |

· |

· |

· |

· |

|

|

Clutch pedal shaft |

· |

· |

· |

· |

· |

· |

|

|

Clutch release bearing |

· |

· |

· |

· |

· |

· |

|

|

Universal joint and intermediate support of transmission shaft |

· |

· |

· |

· |

· |

· |

|

|

Steering knuckle and front axle |

· |

|

· |

· |

· |

· |

|

|

Leaf spring pin |

· |

At least once every four weeks |

|||||

|

Check leaf spring slide rail clearance of suspension |

· |

· |

· |

· |

· |

· |

|

|

Shock absorber mounting |

· |

· |

· |

· |

· |

· |

|

|

Gearshift lever bracket |

|

· |

· |

· |

· |

· |

|

|

Brake camshaft and brake arm |

· |

· |

· |

· |

· |

· |

|

|

Towing hook |

· |

· |

· |

· |

· |

· |

|

|

Fifth wheel |

· |

· |

· |

· |

· |

· |

|

|

Cab door hinge |

|

|

· |

· |

· |

· |

|

|

Perform rust-proofing treatment of driver’s cab again according to schedule |

|

Once every 12 months |

|||||

Note: After cleaning the vehicle, re-lubricate all the parts which need lubricant at once, once a week for the vehicle operated on construction site.

Mandatory Maintenance

1.Purpose

Remove and clean the particles, burrs and other harmful impurities caused during the initial operation of vehicle, solve the connections loosening problems resulting from the initial operation, carrying out a mandatory running-in maintenance, to improve the reliability, so that make the vehicle in the best working condition to extend the service life of vehicle.

2.Implementation

Special service stations authorized by CNHTC can implement the mandatory service.

3.Mileage Requirement

The vehicle can enjoy a mandatory maintenance with the Warranty and Maintenance Manual of CNHTC, if the mileage is between 2000 to 4000 kilometers and within six months.

4.Content

Please refer to the First-time Check of Table 2 for the details of checking.

Engine Maintenance

1. Operation Attentions and Maintenance

For driving safety, the engine must be carried out routine inspections of each component. If somewhere is abnormal, the vehicle should be sent to the repairing service station for maintenance.

Before running the diesel engine, the height of cooling level, fuel and oil level, and diesel level will be checked.

When the diesel engine is started, if it doesn’t work within 15 seconds, restart it after 2 minutes.

After diesel engine is started, idle speed running will last for 2-3 minutes. Fuel pressure will exceed 100,000Pa. When cooling water temperature is lower than 600C, do not run the engine at high-speed and heavy load at once, otherwise its wear resistance and reliability will be affected.

In the case that the engine working with load, load and speed must be reduced before shutdown. Idle speed running must last for no less than 5 minutes.

During running-in period (within 3000km), it is suitable for diesel engine to run only under medium load.

2. Routine Inspection and Maintenance

2.1 Oil Level Check

Check must be carried out after engine shuts down for 5 minutes with the vehicle parked on level ground. When the engine is running or the vehicle is tilting, the oil level could not be measured accuratly.

Checking Methods:

1. Pull out the oil rule, clean the oil.

2. Re-insert the oil gauge completely, and then pull it out again, check the oil level. If the oil level in the grid within the region , it indicates that it is normal.

3. If it lacks of the oil, please fill oil. When refueling, do not exceed the "maximum" of oil gauge.

4. After using, re-insert the oil gauge correctly. Do not let the oil spill all around during refueling. Prevent the oil spills on other components of the engine to avoid danger.

2.2 Coolant Level

Check whether the coolant water level is adequate or not.

Check the coolant level and add the coolant after the engine is cool.

The reason of sudden dropping in coolant level may be the leak of cooling system, please go to service station for maintenance.

Oil Change Interval of Diesel Engine in Maintenance Rules

|

Service Conditions Items |

WGⅠ |

WGⅡ |

WGⅢ |

|

Annual mileage less than 20,000km |

Annual mileage less than 60,000km |

Annual mileage less than 60,000km |

|

|

After running 1000~1500km |

After running 1500~2000km |

After running 1500~2000km |

|

|

Routine Check (P) |

Every 5000km |

Every 1×104km |

Every 1.5×104km |

|

1st-Grade Service (WD1) |

Every 1×104km |

Every 2×104km |

Every 3×104km |

|

2nd-Grade Service (WD2) |

Every 2×104km |

Every 4×104km |

Every 6×104km |

|

3rd-Grade Service (WD3) |

Every 4×104km |

Every 8×104km |

Every 12×104km |

|

4th-Grade Service (WD4) |

Every 8×104km |

Every 16×104km |

Every 24×104km |

Maintenance Range of Diesel Engine

|

Diesel Engine Maintenance Items |

First-time Check |

P |

W1 |

W2 |

W3 |

W4 |

|||||

|

Replace diesel oil (At least once a year) |

● |

● |

● |

● |

● |

● |

|||||

|

Replace fuel filter or filter element |

● |

When changing diesel oil |

|||||||||

|

Check and adjust valve clearance |

● |

|

● |

● |

● |

● |

|||||

|

Repalce fuel filter element |

|

|

● |

● |

● |

● |

|||||

|

Clean fuel prefilter or replace filter element |

|

|

● |

● |

● |

● |

|||||

|

Check coolant volume and add it to full |

● |

● |

● |

● |

● |

● |

|||||

|

Replace coolant |

According to table 4 |

||||||||||

|

Fasten cooling pipe clamp |

● |

|

|

|

|

|

|||||

|

Fasten inlet air pipe, soft tube, and flange connection parts |

● |

|

● |

● |

● |

● |

|||||

|

Check air filter maintenance indicating light or indicator |

|

|

● |

● |

● |

● |

|||||

|

Clean dust cup of air filter (Excluding automatic exhausting type) |

|

● |

● |

● |

● |

● |

|||||

|

Clean main filter element of air filter |

When indicator light or it indicates red |

||||||||||

|

Replace safety filter core of air filter |

After cleaning main filter core for five times |

||||||||||

|

Check bearing clearance of turbocharger |

|

|

|

|

|

● |

|||||

|

Check, adjust clutch stroke and wire rope conditions |

● |

● |

● |

● |

● |

● |

|||||

|

Electric components and electronically controlled system wiring harness |

Check it every 250 hours |

||||||||||

|

Note: ● The mark means that the maintenance is needed. |

|||||||||||

Fuel Oil, Lubricating Oil, Coolant and Auxiliary Materials Used in Engine:

1. Fuel Oil

Summer: diesel which apply to the local market in summer.

Winter: diesel which apply to the local market in winter.

2. Lubricating Oil

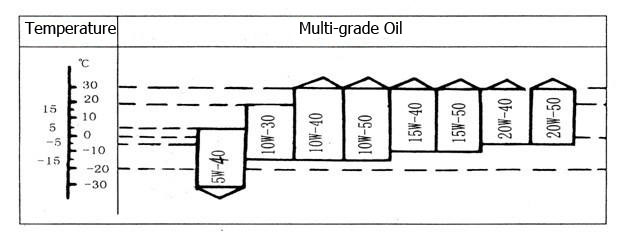

2.1 Grade CF-4 15W/40 engine oil is recommended.

2.2 High-grade oil is allowed to replace lower-grade oil.

Before starting the engine, check the height of the oil within the oil pan.

As the multi-grade oil with a flat viscosity curve, between the range of lubricating low temperature and high temperature, it has good lubricating characteristic, so we recommend use multi-level lubricant.

Changing Engine Oil:

Check whether the oil color is normal and extraneous matter is mixed in oil or not when discharging the oil, so as to detect hidden errors. After the oil is to be drained completely, clean the drain plug and then tighten it; replace with new oil filter element, the new oil should be added into the engine to the upper limit of oil ruler. In order to prevent the case that starting the engine without lubrication, turn the key switch to the starting position (Position 4) when the high-pressure oil pump is in the off position, empty running for a while, and then start the engine and operate in low speed. Check oil filter if there is any leaks, shut down five minutes later, check and add oil to the upper limit.

3. Grease

Inject the general lithium grease into the oil cup of water pump in line with the requirements of the local market.

4. Coolant

Cooling system should be added with the long-acting cooling fluid, this fluid has capability of antifreeze rust. Please refer to the ratio of long-acting coolant antifreeze instructions.

Warning:

1. When temperature is below 0℃, you should check the antifreeze concentration regularly.

2. Vehicles perennial running at areas above 0℃, water which has been treated with anti-rust and

anti-scaling could be used as the coolant; it is prohibited using untreated water as the engine coolant.

Transmission Maintenance

1. Usage Requirements

Operate the transmission properly, and implement regular servicing and maintenance, which is crucial for vehicle’s reliable driving and the transmission’s long life expectancy. Please comply with the following requirements for use:

1.1 Lubricant Brand

Please fill and inject 85W/91GL-5 vehicle gear oil in the transmission.

1.2 Proper Oil Level

Please make sure that the oil level is abreast with the observation slit of oil level. Check the oil level through the observation slit on box flank until the oil level reached the slit and spillage happens. The oil injection volume is about 12L for HW18710 transmission (12.5L with power take-off added).

1.3 Inspection of Oil Level

Regular inspection should be made to the oil level. The car should be parked on flat road when checking the oil level. Considering the inflation of hot oil, do not immediately check the vehicle that is just parked, and only when the oil level is stabilized and the oil temperature comes close to the ambient temperature can we check the oil level, to prevent the inaccurate measurement.

1.4 Re-supply of Lubricant

To prevent the chemical reaction of different kinds of lubricants, the re-supplied lubricant should be identical with the former lubricant brand and specifications.

1.5 Cycle for Lubricant Replacement

Discharge the used lubricant in the transmission and then rinse the strainer assembly when replacing the lubricant for transmission.

The lubricant in the new transmission must be replaced between 2,000~5,000km.

For each 10,000km, the lubricant must be checked for its oil level and leakage. It should be supplemented and the strainer can also be rinsed at any time if necessary.

For each 50,000km, the lubricant must be replaced.

1.6 Working Temperature

The maximum temperature for transmission during the continuous working period must not exceed 120℃ and its minimum temperature must be below -40℃.

The lubricant will decompose and reduce the lifetime of transmission if the working temperature exceeds 120℃.

Any of the following conditions can cause the transmission’s working temperature to exceed 120℃.

① Continuous driving at the speed no more than 32Km/h.

② Engine speed is too high.

③ Ambient temperature is too high.

④ Transmission is surrounded by eddy current.

⑤ Exhaust system is too close to the transmission.

⑥ Running at high-power and over-speed rotating.

1.7 Working Inclination Angle

The working inclination angle for transmission must not exceed 150, otherwise, it may not be fully lubricated (the working inclination angle is equal to transmission’s installation angle on the chassis plus slope angle).

1.8 Draging and Sliding

When the transmission works, its countershaft rotates and drives the oil pump to run, plus splash lubrication, which can fully lubricate the transmission. When the vehicle is dragged with rear wheels touching the ground and transmission system connected, the main shaft rotates comparing to main shaft gear and the planetary mechanism also rotates, although the countershaft gear and main shaft gear for main transmission do not rotate. This will cause great damage to the transmission’s planetary mechanism and localization elements of main shaft due to insufficient lubrication.

Pay attention to the following points to prevent this kind of phenomena:

Do not step on the clutch pedal to let the vehicle slid on neutral position.

When the vehicle needs to be dragged, draw the half axle out or disconnect the drive shaft, or have the driving wheel dragged liftoff the ground.

2. Precautions

2.1 The clutch must be completely released and the gear shaft lever should be moved into relevant positions when shifting.

2.2 When parking, the gear shaft lever should be moved into neutral position in low gears area.

2.3 When shift into low gear (Creeping gear) or reverse gear, it must be stopped first and then shift into relevant gear to prevent the parts inside the transmission from being damaged.

2.4 When the transmission shifts from low gears to high gears (vice versa), do not skip gears, or it will influence the lifetime of auxiliary gearbox’s synchronizer.

2.5 When driving downhill, shifting between high and low gears is prohibited.

2.6 Shift to first gear or second gear to move in accordance with the road conditions.

2.7 Release the brake before the vehicle starts. For the vehicles that equipped with air cut-off brake, do not shift to relevant gear and start until their brake valves are connected and the air pressure reaches the level required to release the brake.

2.8 On the event of any unusual phenomenon, such as abnormal sound or heavy operation during the use of transmission, the vehicle must be parked immediately to check for any failure. Do not continue driving until the failure is eliminated.

2.9 The transmission is featured with interlocked mechanism for main and auxiliary transmission. The gear shifting for main transmission is locked up before the auxiliary transmission shifts into relevant gear. In the event any failed shifting, it may be affected by the interlock of main and auxiliary transmission. Check the sequential gear shifting cylinder and its gas pipeline to ensure that auxiliary transmission has shifted into relevant gear.

2.10 Privately disassembly/knock down or assemble the transmission is strictly prohibited within warranty period.

Front Axle Maintenance

1. Regular maintenance and care of front axle every 15,000km or every six months.

2. Check rotation of wheel bearings, replace grease, and check whether the wheel bearings can continue to use, adjust or replace

it if necessary; the grease used in wheel hub bearings, brake camshaft and the main pin, tie rod ball pins, brake gap adjustment

arm, etc. is for motor vehicles through the lithium-based grease.

3. Grease Volume:

3.1 Volume of grease for each wheel: at a total of about 0.6kg for wheel hub cavity and two bearings;

3.2 Each brake camshaft and the kingpin of the grease volume: approximately 0.2kg, adding to the bracket with the oil gun until

overflow from the holes;

3.3 Tie rod ball pins, brake lash adjuster arm should be filled with grease.

Rear Axle Maintenance

1. Maintain Lubricant Volume, and Frequently Check Oil Volume of Wheel Reductor and Main Retarder.

Oil lacking may lead to early wear of running components and even cause burning damage. While, more lubricant does not mean that it will provide better performance, because excessive lubricant may result in high temperature and even oil leakage.

For new vehicle’s initial maintenance, when replacing lubricant of the wheel reductor, rotate the wheel till drain plug is in the lowest position while filling plug is in the position near half height of the axle housing. Open the drain plug to drain out used oil, screw it back and open the filling plug to fill lubricant to its height, and then screw back the filling plug. Rotate the wheel for several times, locate it in the position where drain plug is in the highest position while filling plug is in the position near half height of the axle housing. Open the filling plug to drain out excessive lubricant till oil level is kept in the height of filling plug, and then screw it back.

There are two screw plugs on the rear axle housing: one is an oil drain plug in the bottom of axle housing, the other is an oil filling plug in the position near half height of the axle housing. The normal oil level should be maintained in the height of filling plug.

The main reducing gear and wheel reductor in rear axle use API GL-5, SAE 85W/90 gear oil. Generally, oil voume is 16.5L for rear driving axle main retarder, 19.7L for middle axle main retarder and about 3L for each wheel reductor.

The oil change interval for rear axle gear oil is 50000km or one year. Gear oil should be replaced for the first 2000-3000 km compulsory maintenance.

2. Operation of Differential Lock

The interwheel differential in rear axle is used to automatically realize speed difference between left and right wheel when the vehicle turns corner so as to avoid tire wear and mechanical damage. Engage the differential lock when the vehicle wheels on one side skids on smooth or muddy road, at this time the left and right axle shaft become one rigidly coupled shaft, thus the vehicle will drive away from the trouble road.

3.Avoiding Serious Overloading

Serious overloading and loading concentration will result in axle housing deforming and break. Therefore, the loading capacity shall be complied with the specified loading in accordance with certain driving conditions.

4.Other Precautions

If the connection fittings such as differential gear and driven gear, etc. need to be reassembled during repairing, smear the coupling threads with Loctite 262 thread setting glue, and tighten the coupling bolt according to the specified torque.

If abnormal sound is heard during operation, do not drive the vehicle, check and repair immediately.

Steering System Maintenance

1. Check hydraulic oil level inside the tank. First, clean oil reservoir and its surroundings to keep dirt out. Pay attention to the oil

stick mark when checking, the oil level should be the same as the oil stick when the engine operates; the oil level should be a bit

higher when the engine does not work.

2. The hydraulic oil of new vehicle needs to be replaced, and cleaned cartridge in the reservoir after the first 2,500Km, and then

each subsequent 20,000Km (or half a year) the vehicle needs to replace the hydraulic oil.

3. Check the oil surface height once a month, and check the cleanliness of hydraulic oil.

4. The procedure for changing oil as following:

4.1 Put up the front axle.

4.2 Open the cover of fuel tank; screw off the return pipe on the steering gear.

4.3 Start the engine, idle running about 10 seconds, and turn the steering wheel to its right and left limit position several times, so as to drain oil from inside the oil reservoir, booster pumps, steering gear.

4.4 Re-tighten the return pipe (keep it clean and keep dirt out of the oil circuit), clean oil reservoir, oil filters and filter elememts. It is best to renew filter element every time when changing oil.

4.5 After filling up hydraulic oil, run the engine at idle speed, turn left and right the steering wheel repeatedly, at the same time, fill oil continuously till oil level no longer reduces and no bubble occurs. The oil level should be added on all the components in the first-grade service.

5.In the first-grade service, check the clearance of every rotary component such as steering tie rod and drag rod joint.

If the clearance is huge, the component should be replaced, and grease should be added on all the components in the first-grade service.

Clutch Maintenance

Running Parameter:

1. Working medium: air and brake fluid;

2. The largest working pressure: 4 MPa for brake fluid, 0.85 Mpa for air;

3. Working temperature: - 40℃~+ 80℃;

4. Brake fluid: complying with DOT3, DOT4 or JG3, JG4 standard;

5. Pedal travel: Max stroke 200mm; free stroke, 25mm for pull, 40mm for push;

6. Pedal force: not more than 190N with assistance.

Adjustment of Clutch Operation System

1. Check and Adjust the Clearance between Master Cylinder Pushrod and Piston:

When adjusting, push the pedal with hand smoothly till the main cylinder pushrod contacts against the piston, then adjust the limit bracket until the clearance between limit bracket and pedal is about 1mm. Tighten the limit bracket nut. Ensure there is 0.5mm~1mm clearance between the pushrod and piston, this clearance should not exceed 1mm, or it will reduce the effective travel and influent the effect of clutch.

2. Adjust Clutch Brake Control Valve:

Step on the clutch pedal fully, at this time the working travel of main cylinder pushrod should not be less than 32mm, and the clutch pedal should have control valve to move 3~5mm. Fix the brake control valve, tighten the bolt, and then adjust the limit screw of the pedal bracket, making the screw cap contact against the clutch against the clutch pedal (when the clutch pedal is stepped down fully). This can prevent the brake control valve from coming off the pedal bracket.

3. Release the Air in Hydraulic System Thoroughly:

Air in hydraulic system can reduce the effective travel of booster cylinder pushrod, and the clutch can’t be released thoroughly, thus shifting becomes difficult.

When assembling and disassembling oil tube, be sure to release the exhaust valve of booster cylinder first. Fill the specified oil to the reservoir. At the same time step on the clutch pedal and release air from the exhaust valve, then tighten it. After stepping on the clutch pedal rapidly for several times, hold the pedal tightly, release the exhaust valve till no air comes out, then tighten the exhaust valve.

Repeat the afore-mentioned steps for 2~3 times, air in hydraulic system will be released completely.

Attentions:

1. During the exhaust process, relax the pedal after the exhaust valve or an associated tube nut is tightened, so as to avoid inhalation of air, lifting the pedal to the maximum height in order to add the brake fluid inside the tank to the master cylinder fluid anvil cell.

2. Re-adjust the clearance when you maintain the new vehicle for the first time. Check the vehicle for second grade maintenance every 12,000km and for first grade maintenance every 4,000km. Push the clutch rocker arm with hand, there should be gap in the head of limit bolt.

3. You must adopt DOT3 or DOT4 brake fluid as actuating medium in hydraulic system. When mounting and dismounting the pipeline, you can use the Loctite572 to seal the union nut and connector.

4. When changing brake fluid, drain the remaining fluid out of the system thoroughly, and change to the specified brand fluid manufactured in the same batch.

5. Brake fluid is corrosive. Avoid brake fluid splashed on the human body and the paint surface of the vehicle during the exhaust process.

Air Conditioner Maintenance

|

Item |

Content |

Check Period |

|||||

|

Every week |

Every month |

Every two month |

Every quater |

Every year |

|||

|

Air-conditioning Unit |

Coolant Volume |

Check coolant level |

+ |

|

|

|

|

|

Coolant Leakage |

Check leakage with halogen checker |

|

|

+ |

|

|

|

|

Hose and Pipe |

Check cracks and damage |

|

|

+ |

|

|

|

|

Check leakage of connectors and tightening of clamps |

|

|

|

|

- |

||

|

Replace desiccant and filter |

|

|

|

|

- |

||

|

Coolant |

Refill with specified coolant |

+ |

|

|

|

|

|

|

Compressor |

Oil Seal |

Check leakage trace with white paper |

+ |

|

- |

|

|

|

Belt |

Check tightness of belt pulley and check wear |

|

|

+ |

|

|

|

|

Bolt |

Check tightness, check and check change all of them, if necessary |

+ |

|

|

|

|

|

|

Evaporator Condenser |

Evaporator Cartridge |

Check dirt, clean if necessary |

+ |

|

|

|

|

|

Wind Motor |

Check running condition |

+ |

|

|

|

|

|

|

Expansion Valve |

Check running condition, remove filter gauze and clean |

|

|

|

|

+ |

|

|

Condenser Cartridge |

Check dirt, clean if necessary |

+ |

|

|

|

|

|

|

Wind Motor |

Check running condition |

+ |

|

|

|

|

|

|

Electrical Apparatus Element |

Connector and Plug |

Check looseness of wire clamp plug |

+ |

+ |

|

|

|

|

Heat Sensitive Resistance Switch |

Check action |

|

|

|

+ |

|

|

|

Magnetic Clutch |

Check if specified requirements has been met |

|

|

|

+ |

|

|

|

Magnetic clutch bearing |

If it can’t turn steadily, please replace it |

|

|

|

|

+ |

|

Specification: "+” indicated adjustment or repair if necessary; “_” indicates replacement.

Battery

Check the surface and proportion of liquid electrolyte every three months. The surface is 10~15mm higher than the electrode plate; the proportion is more than 1.24 g per cm3.

Take off the battery into the warmer room when the vehicle does not run for a long period and the temperature is low.

Check whether the battery electrode pile and wire connection clip is loose and the battery conditions are normal or not when the vehicle runs for each 500 km.

Changing and Replacing Parts

Your vehicle is designed based on the latest technical knowledge of security, so it provides excellent active and passive safety. In order to maintain this state, it is forbidden to change parts arbitrarily. So if the vehicle must be added other accessories, carry out technical improvement or replace parts, pay attention to the following instructions:

Before purchasing the accessories and parts for replacement or technical improvement, ask for the CNHTC sales agencies’s advice first.

CNHTC sales agency provides original accessories, parts and components, and professional installation services.

We suggest using original accessories and parts only, and installing them at CNHTC service agency. Due to the damage caused by violation of operation, CNHTC service agency does not provide quality assurance.

If the additional installation of the accessories which will directly affect the driver's control of the vehicle, such as speed control devices, these devices must get CE (European Community recognized mark) or "CCC" mark which approve equipment can be installed in your models.

If the connected electrical equipment does not directly control the vehicle, such as refrigerators, horns, or fan, CE (European Community recognized mark), or "CCC" mark should be attached to them.

If your vehicle needs technical midification, please note our principles, that is, do not modify the vehicle without our permission; do not perform to damage the vehicle; the transportation safety and operating reliability should be ensured. CNHTC service agency will provide professional service or introduce professional state under particular cases.

Notice:

Reliability, security and acceptability of the original accessories and parts have the approval and is suitable for the vehicle.

For other brand parts and components, we could not provide quality warranty, even if they have offical approval from the technical inspection supervision authorities’ acceptance.

For unauthorized vehicles modification and the adverse consequences caused by the modification, no warranty will be provided.

Frequently-Used Vehicle Data

Volume Data

|

Assembly |

Petroleum Product |

Brand |

Volume |

|

|

Fuel tank capacity (L) |

Diesel |

Solidifying point in summer<0°C |

GB252 Excellent grade 0# light diesel oil |

400 or 300 |

|

Solidifying point in winter<-20°C |

GB252 Excellent grade -20# light diesel oil |

|||

|

Engine Cooling system (L) |

Long-lasting antifreeze anti-corrosion coolant |

Heavy duty long-lasting antifreeze anti-corrosion coolant used in four seasons |

40 |

|

|

Engine Lubrication system (L) |

Engine oil |

15W-40 CD Grade |

27 |

|

|

Transmission (L) |

Gear oil of heavy duty vehicles |

85W/90 GL-5 |

13 |

|

|

Clutch (L) |

Brake fluid |

SAE 116/ DOT3 |

About 1L |

|

|

Steering (L) |

Hydraulic liquid |

HVN32 Low temperature hydraulic liquid |

3.5 |

|

|

Rear-axle final drive and bush bearing (HW1697 Rear axle)(L) |

Gear oil of heavy duty vehicles |

GL-5EP 80W/90 or GL-5EP 85W/140 |

23 |

|

|

Rear-axle final drive and bush bearing (STR Rear axle)(L) |

Gear oil of heavy duty vehicles |

GL-5EP 80W/90 or GL-5EP 85W/140 |

23 |

|

|

Tilt-cab assembly(L) |

Hydraulic liquid |

HVN32 Low temperature hydraulic liquid |

0.4 |

|

Adjusting Data

|

Travel of clutch pedal (Free travel)(mm) |

Pedal |

40 |

||||

|

Brake Shoe Clearance (mm) |

0.6~1 |

|||||

|

Travel of brake chamber push-rod (Travel of piston rod)(mm) |

57 (min) |

|||||

|

Air pressure of tyres (kpa) |

Type |

9.00-20 |

10.00-20 |

11.00-20 |

12.00-20 |

|

|

Single tyre |

700 |

740 |

740 |

740 |

||

|

Dual tyre |

770 |

810 |

810 |

810 |

||